Benefits

Reduced operating costs

- Low electricity consumption with the unique, short wave IR preheating system, cleverly designed for precise control of heating depth; no chiller or vapour handling system

- Zoned lamps ensure maximum energy efficiency

- Easy access to all areas for service and maintenance

Excellent quality & improved productivity

- Create high quality thermal plates, comparable to solvent quality, in about 1 hour from imaging to finishing

- Convenient front side loading and unloading of the plate and nonwoven; Jumbo nonwoven rolls allow for up to 39 full sized plates to be processed before exchange

- The clever design and technology incorporated keeps maintenance to an absolute minimum with normal uptime of 99.7% and remote diagnostics via Wi-Fi

Sustainability and health & safety

- Near elimination of VOCs, low energy usage, and up to 30% less fabric in our developer rolls will substantially contribute to your sustainability efforts

- Convenient and safe developer roll transport, loading and unloading with specialized handling lift cart

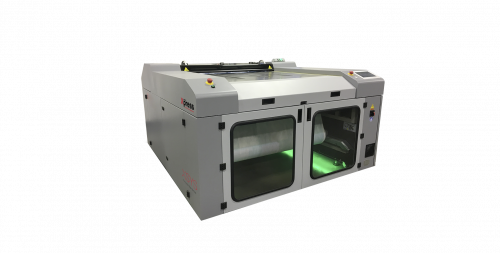

Specifications

Maximum plate size (W x L)

1270 mm x 2032 mm (52" x 80")

Minimum plate size (W x L)

813 mm x 305 mm (32" x 12")

Plate thickness

1.14 mm – 2.84 mm (0.045" – 0.112")

Electrical connection

230 V/ 50/60 Hz/ (3 Ph/PE) – 26.6A

Electrical connection (alternate)

400 V/ 50/60 Hz /(3 Ph/N/PE) – 15.3A

Nominal power

10.6 kW

Compressed air

3/8" NPT/ 6.5 bar/ 2.0 m³/h/ (95 PSI/ 1.2 SCFM)

Ethernet connection

RJ45

Exhaust air

Ø 8" (203.2 mm)/ min. 1019 m³/h/ (600 SCFM)

Ambient conditions

65° - 80°F (18°- 27°C)

Weight (uncrated)

2265 kg (5000 lbs)

Dimensions (W x H x L)

2115 mm x 1245 mm x 2345 mm (83.25" x 49" x 92.3")

Weight (crated)

2627 kg (5800 lbs)

Crate dimensions (W x H x L)

2235 mm x 1575 mm x 2540 mm (88" x 62" x 100")